PRODUCTS CERTIFICATION

Certified heating elements, safety tests and quality certificates

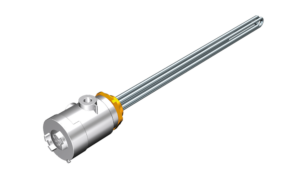

Our full range of products (electrical heating elements and systems) comply with EN 60335-1 and meet the essential requisites of the Low Voltage Directive and current legislation regarding safety for electrical materials.

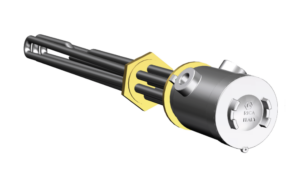

Special products that operate in explosive atmospheres where there is an explosion hazard, comply with the requirements of the ATEX Directive and the IECEx Certification Scheme; these products are respectively covered by the EC type examination certificate and IECEx certificates of conformity (CoC).

Certain products also comply with Machinery Directives and PED, when necessary they are included in the scope of these Directives.

At customers’ request heating elements and systems are certified by UL/CSA or VDE, or to other standards for the specific application.

Since 1992 our polyimide etched foil heating elements have been ESA approved for use in space applications. In compliance with current standards, this approval is renewed every two years and recorded by ESA-EPPL with approval certificates No.184 and No. 330.

Products certification is carried out in our own laboratories by Quality engineers, who co-operate with the certification authority’s engineers. The laboratories where the tests are performed are qualified to the applicable standards and regulations and operate to the Client Test Data Program for UL/CSA certification.

ZI Heating Element Technologies outsources chemical analyses, raw materials tests (steel, oxides), corrosion and mechanical tests, or the issue of electro-magnetic compatibility certificates to current regulations.

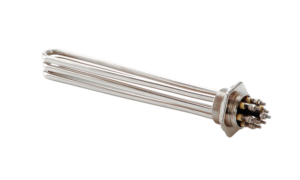

All ZI Heating Element Technologies production is 100% tested, and if required by the customer supplementary safety tests and controls are performed and the relative approval certificates and declarations of conformity are issued by the Outgoing Quality Service.

To assist partnerships products are co-designed with customers and the prototypes are subjected to life tests not only for components, but also for the final equipment incorporating the component.