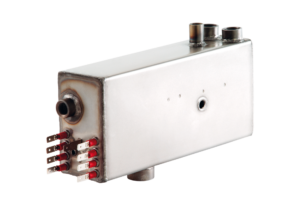

Applications

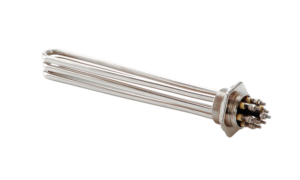

- Medium viscosity oils, non-flowing heat transfer oil etc.

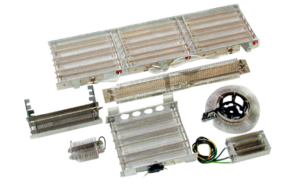

Standard features

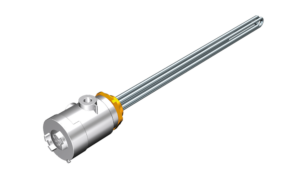

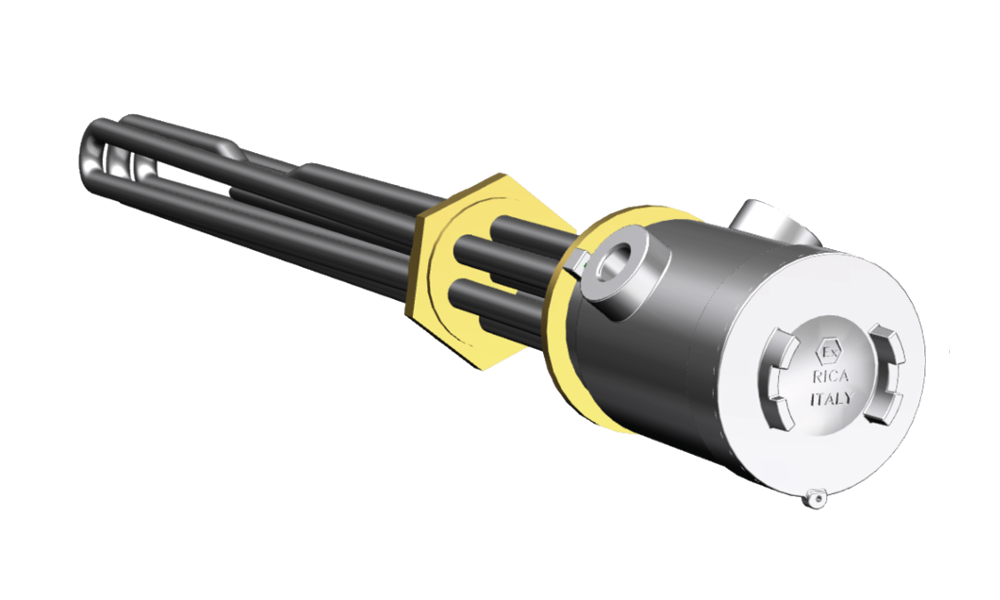

- rugged industrial construction

- stainless steel elements

- 1 ¼” brass screwed plug

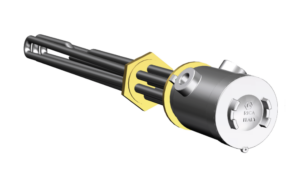

- Explosion-proof terminal enclosure with stand-off

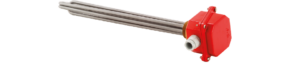

- Thermostat manual reset cutout

- Thermostat for regulation

- Thermowell optional

Get in touch